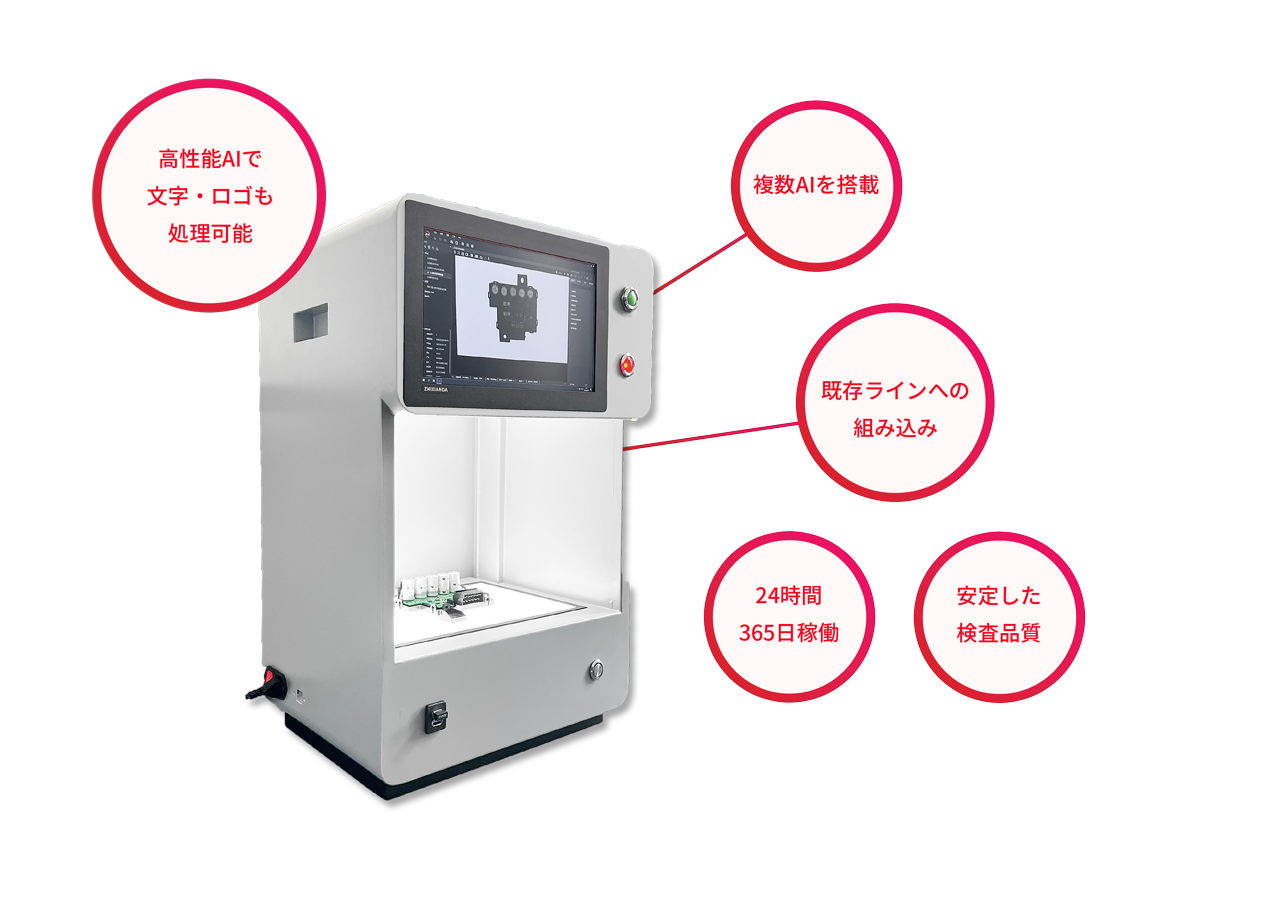

AI camera inspection

Automation solution for

inspection process with high precision and stable quality

With a graphical interface and built-in powerful deep learning algorithms, it solves complex problems such as highly difficult defect inspection. It also eliminates the need for sanitary measures such as changing into a clean suit and washing hands, making medical and food factories more efficient.

POINT

Highly accurate inspection possible with multiple cutting-edge AI

Even when it is difficult to accurately detect and distinguish defective products by using AI alone, we can boast high inspection accuracy by combining multiple AIs.

24-hour operation and 365-day operation with stable inspection quality

In visual inspection, the accuracy of inspection varies depending on the ability of the individual, but RBB's inspection robot can maintain a constant inspection quality. It operates 24 hours a day, 365 days a year, with no holidays.

Can be integrated into existing lines

The unit can be installed on a variety of lines such as conveyor lines and visual inspection lines. It can also be retrofitted into existing lines.

The space-saving design of the housing allows it to be installed in any location.

Can be introduced to suit a variety of lines. It can be retrofitted into existing lines.

Achieving speedy and stable inspection quality.

Capable of high-speed automatic inspection of 180 items per minute.

AI learns from a single defective product image. Significantly improves the accuracy of visual inspection automation.

Improve productivity by operating 24 hours a day, 365 days a year

Introduction example

movie

商品仕分け